LARGE FORMAT 3D PRINTING

Trusted

BY LARGE ORGANIZATIONS AND SMALL BUSINESSES NATIONWIDE

2x4+ 3D PRINTING

Application in Automotive

Case Study #1 speed up prototyping time by 75%

Ivan Tampi Customs has already adopted MAKEiT 3D printing technology. He is no longer making clay models by hand. After printing, Ivan was able to test fit the real-sized fender prints right away on his new build.

The material used is PA6GF/ nylon glass fiber filament. These prints are stiff, lightweight, easy to sand with a power sander.

Unlike PLA, PA6GF doesn’t melt, nor deform. It works well with fillers and epoxies during post-processing and mold making. Ivan is very pleased with this new fabrication process.

“MAKEiT 2X4 large format 3D printer has saved me 75% of prototyping time. I’ve used the printer a lot to make prototypes and master molds. The turnaround time from design to reality is so fast!!”

Ivan Tampi

The owner of Tampi Enterprise, Inc.

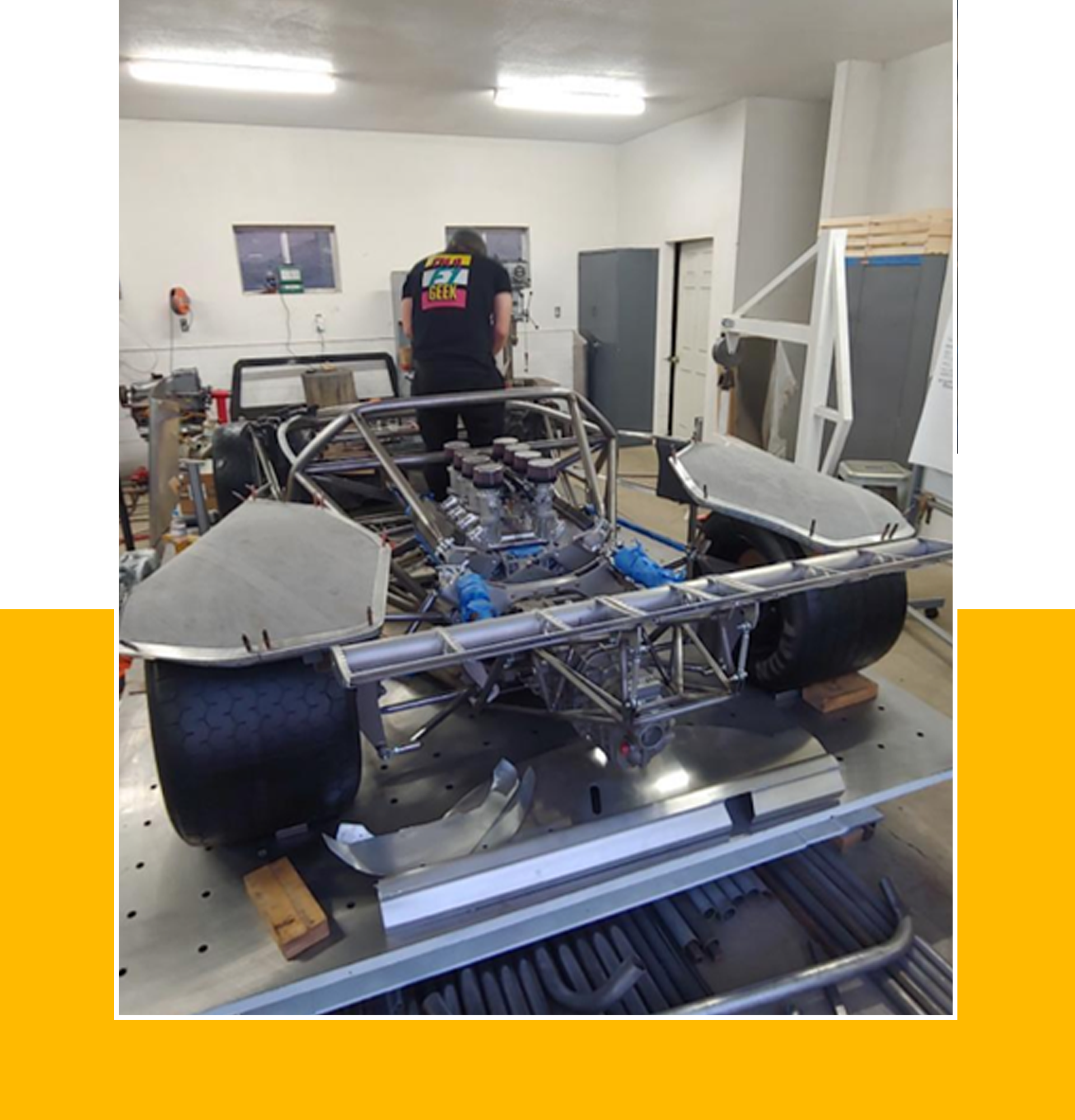

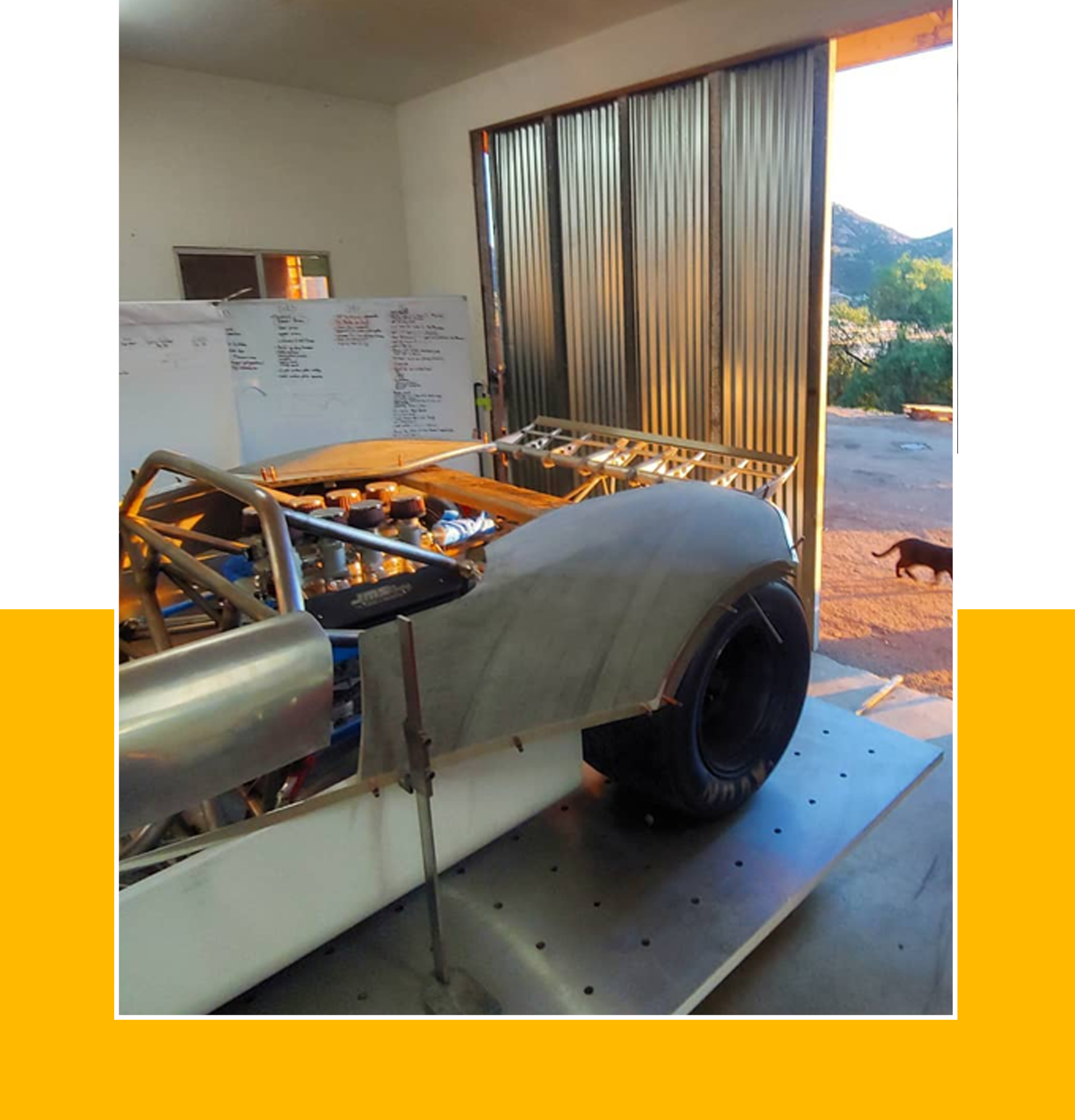

Case Study#2 “shaping METAL SHEET FAST WITH 3D PRINTED FULL SURFACE buck

Jake, the owner of Flying Dutchman Industries, is a pioneer and futurist. For many years, he has built specialty cars and motorcycles with traditional bucks and wireframes.

Section bucks / wireframes are commonly used tools to aid metal shaping. When it’s time to shape a car's body surface with lots of detailed design, using this standard tool can be challenging, since they only represent a skeleton of the design. Bucks do not have continuous surface areas as references. Fabricators have to eyeball the pattern and fill the empty space with their imagination. Not only is this process time consuming, but also inaccuracy and errors occur often. It is especially challenging to create and preserve the symmetric flow of the left and right side of a car body.

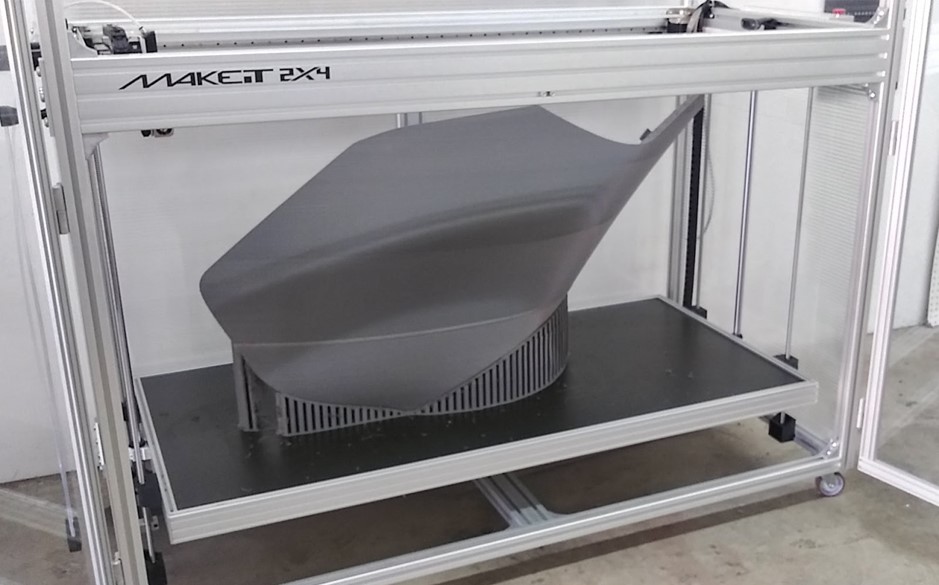

Aware of the advantages of 3D printing and the limitations of traditional bucks, Jake asked himself, “What if we 3D print the entire buck?” He began to explore new ways to take advantage of MAKEiT 3D printing technology and put it to good use in the traditional metal shaping world.

Straight from the CAD design, these complex shaped fenders are 3D printed on our MAKEiT2x4+ large format 3D printer. The entire passenger side fender shape is printed in one single piece. Using the “Mirror” technique, the driver’s side fender is also digitally produced next by MAKEiT 2x4+ printer to complete the pair, ensuring perfect symmetry.

Complex fender shape details, such as curve lines and edge finishing, are captured and reflected on the 3D printed fender bucks. They provide Jake accurate touching points through the metal shaping process, and they serve as excellent guides to complete the metal edge finishing.

No more guessing work! 3D printed full surface bucks provide accurate, fast and symmetrical patterns for metal shaping. It has taken Jake only ONE day to shape these two complex fender metal skins. Without the 3d printed bucks, it would have taken 3-4 days to complete the task.

A 3D printed car buck needs to be stiff, strong, and sandable. It needs to work well with fillers and epoxies. Polyamide PA6GF filament made by Polymaker can meet that need. The surface of an unfinished, freshly printed fender buck is rough, with printed supports attached here and there. By using an orbital sander with 80 grit, Jake can easily remove the support materials and other debris on the surface. During the sanding process, the Nylon glass fiber part remains stable. It is not affected by the heat at all, unlike a PLA print which would soften and melt. Additionally, the nylon glass fiber bucks are strong enough that Jake was able to hammer the metal skin over the printed buck to adjust angles and achieve a net fit. It gives superior edge control.

For Flying Dutchman Industries, MAKEiT 3D printing technology has improved the old metal shaping process tremendously. His productivity has been elevated to the next level. Now he is prepared for new opportunities that were never imagined before…

To learn more about Jake’s metal shaping practice with 3D printed buck, follow him on his Instagram: @flyingdutchmanindustries

Case study #3 Creating Guinness World Record

The full service production company Atomic Props and Effects is an expert in the advertising industry. They bring people’s ideas on the napkin to real life.

On Saturday Feb 5th 2022, we witnessed the historical event in Southern California. The Guinness World Record did the survey and officially announced that Atomic team has created a new Guinness World Record: the tallest 3D printed human statue.

This statue is close to 20ft tall, 3d printed with PETG carbon fiber material. We are so proud that 2 of MAKEiT2x4 large format 3D printers were used to 3D print sections that needed more details as shown here. Together with another printer, the talented Atomic team has made history!

Case Study #4 ReUsable Mold Made with 3D Printing

Meet Omar, a talented mechanical engineer at SpeedConcepts. Omar made a custom body mold for a KTM race bike. Instead of traditional methods, he harnessed the power of the MAKEiT 2x4 large-format 3D printer to bring the mold design to life.

Why 3D Print A Mold?

3D printing offers several compelling advantages over conventional manufacturing techniques:

-

Time Efficiency:

Traditional mold-making often involves lengthy processes like machining or carving, which can be time-consuming. 3D printing streamlines this by producing the mold directly from digital designs, significantly reducing production time.

-

Streamline production process:

The mold is produced in a single print run, minimizing the need for assembly and reducing potential points of failure.

-

Design Flexibility:

3D printing allows for the creation of complex and intricate designs that are difficult or impossible to achieve with machining or carving. Detailed features can be made into the mold design on a computer without additional steps.

-

Cost Savings:

No custom tooling cost

-

Keep high quality and precision of the mold

Material Selection: Glass Fiber Nylon

The glass fiber nylon is the go-to filament for mold-making. Its strength and thermal resistance enable the regular post processing, such as filling and sanding, to be finished easily, no melts, no deform.

Conclusion

Omar's innovative use of the MAKEiT 2x4 3D printer exemplifies how modern technology can revolutionize traditional manufacturing processes. By embracing 3D printing, he achieved a high-quality, detailed mold efficiently and cost-effectively in racing component fabrication.

ProDucts & Services

You can depend on it to print your next large project!

MAKEiT2x2 & 2x4+ large format 3D Printers are high-performance workhorses handcrafted with pride in California. You will be able to run a single print as massive as 55x26x31in/1400x650x800mm. That means a full-size spoiler can be 3d printed in one run; or a C7 hood can be printed in two halves in two runs. Say goodbye to puzzling, gluing and aligning small prints made by a small printer.

3D print your next projects, large parts, or plugs/ full surface bucks/master molds, with MAKEiT large format 3d printing technology. It may save up to 75% of your prototyping time, with much less handwork and guaranteed accuracy and symmetry!

Even better, MAKEiT2x2 & 2x4+ 3D printer specializes in printing PA6GF-glass fiber nylon, or PA6CF-carbon fiber nylon filaments! These industrial grade materials are stiff, lightweight, high heat-resistant (PA6GF heat deflection temp is at 375.8F/191C), easily sandable with an orbital power sander, no gummy, no melts, no deformation. You can use existing skills and existing fillers / epoxies to do the post-processing work as you have done it million times.

Every MAKEiT printer is fully assembled in our shop. It has done large scale print tests over 50hrs before it is shipped. Besides getting a fully functional machine, bonus tool kit, you will also receive a large sample print that is printed on your printer. This is the last print before we package it for shipping.

Our goal is to:

- Deliver a high quality dependable machine.

- It enables you to start a decent print once the auto calibration & auto-leveling processes are done.

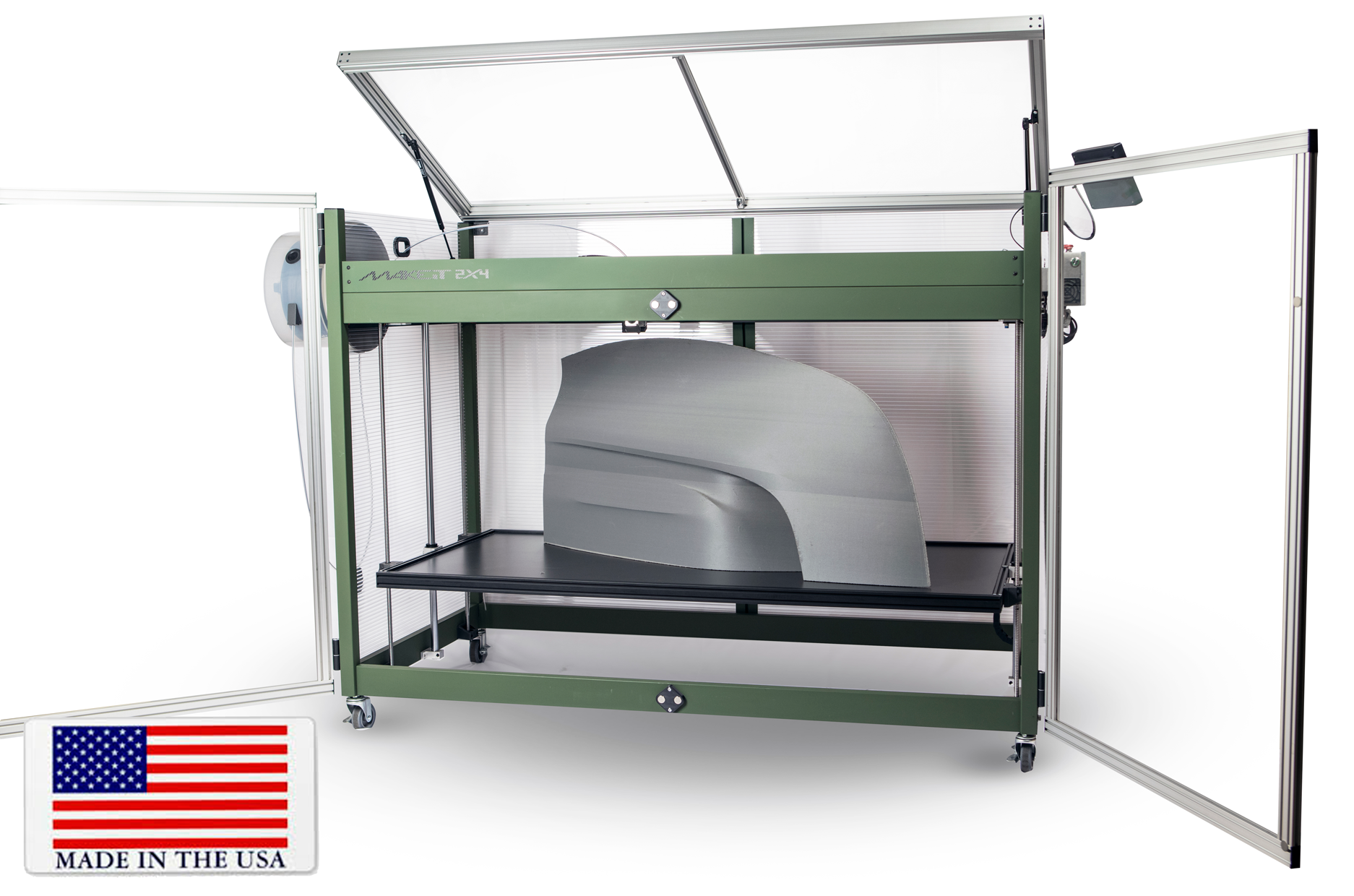

MAKEIT 2x4+

3D PRINTER

You are able to print a part as massive as 55x26x31in or 1400x650x800mm on a MAKEiT 2x4+ large format 3D printer!

Producing industrial grade Glass Fiber Nylon or Carbon Fiber Nylon prints is our specialty. Thanks to many automated processes on board the printer, it’s easy to operate, dependable to produce.

MAKEIT 2X2

3D PRINTER

How big can I print? MAKEiT 2x2 large format printer is capable of 3D printing a glass fiber nylon or carbon fiber nylon part as big as 26x26x31in, or 650x650x800mm. Thanks to many automated processes on board the printer, it’s easy to operate, dependable to produce.

3D PRINTING SERVICE

Please send us the stl file first for evaluation and free estimate. We will contact you to go over the possibility of 3D printing your part. Please note not every CAD design is a good fit for the 3D printing process. The call is especially necessary for the first timer trying out 3D printing.

TESTIMONIALS

HERE'S WHAT OUR BUYERS HAVE TO SAY

"I have used the MAKEiT 2x4 3D printer for a few years now. It is a capable and reliable printer. Having a large format printer is a game changer. Things that I would have never considered for 3d printing before are now just simple tasks. I no longer need to glue smaller prints together. That saves time, labor and aggravation. It also eliminates the need for secondary machining to correct misalignment and eliminate parting lines. I really like the ability to print multiple materials. It makes it very flexible especially when I have certain design criteria to meet. The 2x4 certainly opens up different opportunities that you normally would not have with a smaller 3D printer.

One of the benefits of working with MAKEiT is that they are the manufacturer. They touch and work on each and every printer. It is not designed here, made there. They have the knowledge pertaining to their products. I can call and get a real person on the other end of the line. Their support is extraordinary. They truly stand behind their reputation as a quality manufacturer. When you buy a product from them, it is not just a purchase, it is more like a partnership. I definitely recommend MAKEiT any of your 3D printing needs."

James T.

General Tool Co.

Adam A.

Chief Engineer of Additive Ai

"The MAKEiT team has been excellent to work with. They support their printers when needed and the user group consists of top-notch individuals. I am very pleased with the quality of components used in the 2X4 printer. My company, “Additive Ai” successfully 3D scans – Designs – and Prints full size car components with a MAKEiT 2X4 Printer."

"MAKEiT 3D printers are the literal workhorse of the 3D printing community, I have had 2 of them running 24/7 for the last 3 months.

When I was tasked to 3D print a 4ft manifold system, the initial solution was to break the model into 9 individual parts and glue them all together. Dissatisfied with this approach I went on a search for a 3D printer that could handle the print volume we required to print this part as one solid piece.

Once I found the 2x4 large format printer I knew this was going to be the machine for the job.

From my 5 years of 3D printing experience, I knew multi day prints in large formats had the potential to layer shift at any moment, which could ruin a project timeline when the piece is a 9-day print. Fortunately the 2x4 printer was designed specifically for this type of application.

Using a closed-loop system on the motors that control the print axis, layer shifting is a thing of the past, AN ABSOLUTE GAME CHANGER!! I was blown away when I saw the video of the print gantry snapping back to its position whenever the operator would drag it from its current print path. You just have to see it to understand how awesome that is.

The build is absolutely beautiful, utilizing premium Japanese extruded aluminum, high-end hot end, aerospace-grade cables, and a full carbon fiber heated bed.

I looked through lots of printers for this project and this one was above all others and about half the price of other printers with similar print volumes.

Although the printer is truly in its own class, the staff at MAKEiT, Inc. are the true reason you should be buying this brand. Shelley and Salomo are always there ready to help with anything print profile-related and have come out to my office multiple times to help me troubleshoot issues. It is awesome to learn about the printer directly from the person who designed it. Learned a lot about how they continue to improve the product to ensure the best user experience. Salomo is a true genius in his field. Give them a call, BUY A PRINTER, you will not regret it. Perfect for any company that is expanding their R&D facility or makers who are looking to scale their project capabilities for more business opportunities."

Armando Barrios

Former Mechanical Engineer at Grow Glide

David Preciado

Owner of 3D Scan OC

"I used to 3D print large composite plugs in many, many small puzzle pieces to then spend hours joining together and furthermore sanding the seams between them. This process of printing multiple smaller pieces to make a large part was growing old. Furthermore, the lack of capabilities and reliability of my smaller 3D printers made projects take a lot longer to complete. It was becoming a roll of the dice as to whether or not deadlines could be met.

Thus my search for a large format 3D printer began.

When it came to large format 3D printers, there were few options available. It was very easy to find yourself receiving quotes for complicated 3D printers that started at $50,000 or MORE! There were some poorly designed and equipped DIY options (Modix) that initially seemed like something I would’ve unfortunately had to settle for but thankfully I found MAKEiT. The 2x4 large format 3D printer is something I can leave running on its own for DAYS without any worries. I’m printing so many of my plugs for composite mold making in one piece and dramatically cutting down the time it takes to get something to market. Additionally, I’m able to print so many automotive parts in a single go. My favorite thing about the 2x4 is that it can do all of this with any of the materials I throw at it thanks to the super capable print head. I VERY reguallary print nylon PA6-GF for so many of my large parts without a single worry of a dreaded print failure.

Thanks to MAKEiT, I can promise my customers that not only do I have the capability of taking on their large 3D print jobs but most importantly that deadlines WILL be met thanks to the trust I have in my 2x4 3D printer."

"“I have a MakeIt-3d 2x4 printer and love it. It is a well built, high quality machine. They took the time to build the machine right and it shows. I am very grateful to have found them.”"

Tony Wanger

Mechanical Engineer & Owner of Open Road Upfitters

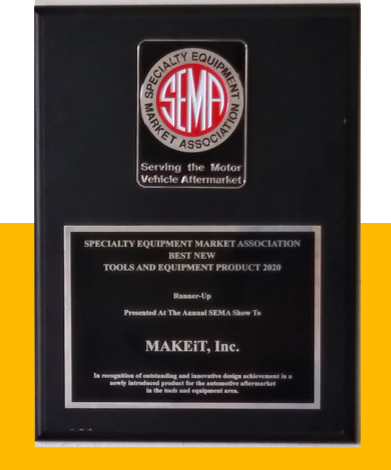

Awards and Recognitions:

SEMA Show 2020 Best New Product Winner

MAKEiT2x4 Large Format 3D Printer is recognized by the industry, has won the 2nd place SEMA Show 2020 Best New Tools & Equipment product out of 3000 new product showcase participants.

MANUFACTURING SOLUTION PROVIDER 2021

Manufacturing Outlook selected MAKEiT, Inc. as one of the Top Ten Additive Manufacturing Solution Provider 2021

SEMA SHOW 2021 GLOBAL MEDIA AWARDS

As a featured new product, MAKEiT2x2 Printer was selected and awarded 2 Global Media Awards at 2021 SEMA Show.

WHO WE ARE

We make quality and dependable large format 3D printing equipment in California for designing, engineering and fabrication firms. After years of working with various car designers and custom shops, we have created and developed a large format 3D printing equipment system suitable to operate in small or large shops 24/7.

It’s easy to learn and operate the MAKEiT printers, thanks to many user-friendly features and on-board automations. You will get factory direct, real person support from our knowledgeable staff based in Los Angeles.

Let’s put MAKEiT2x4+ & MAKEiT2x2 printers to perform, transforming your next digital design from a computer vision to a life size project faster, with less handwork.

FREQUENTLY ASKED QUESTIONS

MOST ASKED QUESTION FROM OUR BUYERS

How long is your lead time?

Our lead time is 6-8 weeks or longer due to shortage of parts

Do you ship to places outside the USA?

Yes, It depends. please send email to information@makeit-3d.com for details.

How do you ship my printer?

Your fully-assembled and tested machine will be securely packed in a custom crate, shipped in LTL or LCL cargo that is handled by a professional shipping company.

-

(626) 872-6618

-

© 2024 MAKEiT, Inc. All rights reserved.